Technology transforms industries by optimizing processes, reducing costs, and driving profits. From precision tools to automation breakthroughs, advancements are reshaping operations daily.

So, let’s explore how innovations can improve productivity and profitability across diverse sectors in meaningful and practical ways.

Precision Monitoring with Flow Meters for Saving Resources and Increasing Profits

Industries like oil and gas or aerospace demand extreme precision. Measurement errors can cost both time and money. That’s where flow meters shine. These devices accurately measure the flow rate, density, or pressure of fluids in pipelines and systems.

High-quality options, such as Turbines Incorporated flow meters, ensure minimal wastage by maintaining precise readings under varying conditions.

For example, chemical processors can reduce material losses by monitoring critical fluid flows more reliably with these tools.

Improved accuracy means fewer operational disruptions and optimized resource allocation—resulting in higher productivity levels overall.

By saving resources through effective measurement techniques, industries can maximize profits while meeting stringent performance standards every day on their production floors.

AI-Powered Predictive Maintenance for Minimizing Downtime

Unexpected equipment failures disrupt operations and inflate costs. Traditional maintenance schedules often miss the mark, leading to over-servicing or overlooked issues. Artificial Intelligence (AI) transforms this approach with predictive maintenance systems.

Using machine learning algorithms, these tools analyze real-time data from machinery to forecast potential breakdowns before they occur.

For example, in manufacturing plants, AI-driven solutions help identify wear and tear on conveyor belts or motors early enough to schedule repairs without halting production lines unnecessarily.

This precision minimizes unplanned downtime and extends equipment lifespans while lowering repair expenses significantly.

By reducing costly interruptions through advanced monitoring techniques, businesses improve operational efficiency and increase profitability over time—all while keeping critical processes running smoothly.

IoT-Enabled Sensors for Revolutionizing Industrial Operations

Industries rely heavily on data for decision-making, but manual monitoring often falls short. Internet of Things (IoT)-enabled sensors to bridge this gap by providing real-time insights directly from equipment and environments.

For instance, in the oil and gas sector, IoT sensors track pipeline pressure, temperature fluctuations, or fluid levels continuously. These systems send instant alerts if conditions deviate from set thresholds.

Early detection prevents costly damages while maintaining operational safety standards.

Beyond monitoring, these devices integrate with automation systems to adjust processes automatically when needed. This reduces human error and enhances efficiency overall.

With smarter workflows powered by IoT-enabled technologies, industries achieve higher productivity levels alongside notable cost savings every step of the way.

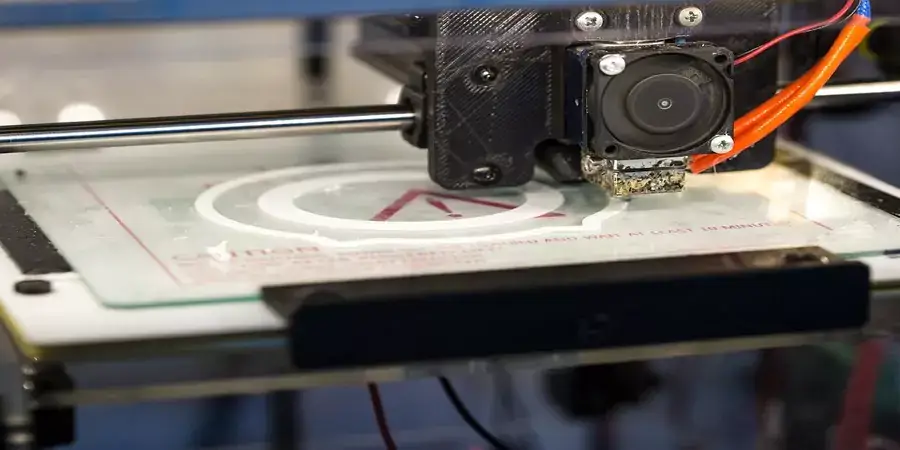

3D Printing in Manufacturing for Reducing Costs and Boosting Output

Traditional manufacturing often involves expensive tooling, long lead times, and material waste. 3D printing changes this by producing components layer by layer directly from digital designs. This eliminates the need for molds or dies.

For example, aerospace companies use 3D printers to create lightweight parts with complex geometries that traditional methods struggle to produce efficiently.

Rapid prototyping becomes faster and cheaper, allowing design adjustments without starting over entirely.

The process also minimizes material waste since only the required amounts are used during production.

Lower costs combined with shorter timelines mean higher profitability on every project scale.

By integrating additive manufacturing into workflows, industries achieve unparalleled flexibility while meeting growing demands effectively.

Advanced Robotics for Streamlined Production Lines

Repetitive tasks and manual labor often slow down production, increase errors, and raise costs. Advanced robotics tackle these challenges by automating complex processes with precision.

For instance, automotive manufacturers employ robotic arms to assemble parts, weld components, or paint vehicles uniformly.

Robots work faster than human counterparts while maintaining consistent quality standards throughout operations. They can also operate 24/7 without fatigue, maximizing output significantly over time.

Additionally, robots reduce workplace hazards by taking on dangerous tasks like handling heavy machinery or toxic substances. This improves safety conditions while cutting down compensation claims and downtime due to injuries.

By incorporating robotics into production lines strategically, industries boost both productivity and profit margins simultaneously.