In the fast-paced world of auto shops, dealerships, and parts retailers, inventory is the lifeblood of the business. Having the right part at the right time is not just a convenience; it’s the core of profitability and customer satisfaction. However, if your stockroom feels chaotic, with parts that are hard to find, inaccurate counts, and a constant swing between having too much or not enough, your business is likely suffering. This feeling of an auto parts inventory that is out of control is a common but critical problem that manual tracking or outdated systems can no longer solve. The solution lies in embracing modern technology designed specifically to bring order, accuracy, and efficiency to this complex environment. Advanced auto parts software is no longer a luxury but an essential tool for survival and growth, streamlining operations and turning inventory management from a source of stress into a strategic advantage.

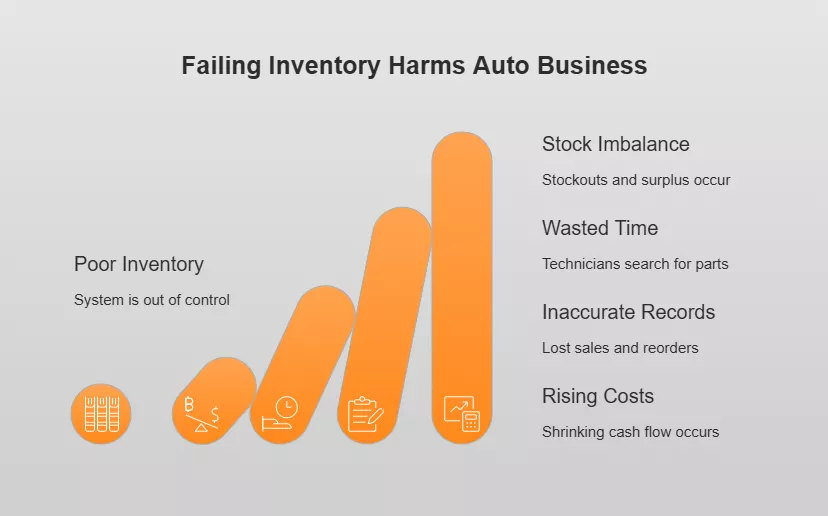

What are the signs your auto parts inventory is failing your business?

Recognizing the warning signs of a failing inventory system is the first step toward correcting a problem that can quietly drain your resources and damage your reputation. These symptoms often start small but can quickly escalate, creating significant operational bottlenecks and financial strain. If any of the following issues sound familiar, it’s a clear indication that your current methods are no longer sufficient and are actively holding your business back from its full potential.

You constantly face stockouts or surplus inventory

One of the most telling signs of an out-of-control inventory is the persistent problem of imbalance. On one hand, you experience frequent stockouts of high-demand components, leading to repair delays, frustrated customers, and lost sales. When a customer’s vehicle is on the lift and you discover a necessary part is missing, the entire workflow grinds to a halt. On the other hand, your shelves are cluttered with surplus or “dead” inventory—slow-moving parts that tie up valuable capital and occupy precious storage space. This situation arises from an inability to accurately forecast demand. Without a system that analyzes historical sales data, you are essentially guessing what to order, which inevitably leads to costly overstocking of some items and understocking of others, directly impacting your cash flow and profitability.

Your technicians waste time searching for parts

Time is money in an auto repair shop, and every minute your skilled technicians spend away from a vehicle is a minute of lost revenue. When your inventory system is disorganized, technicians can waste significant amounts of time physically searching for parts, verifying stock levels, or correcting inaccurate records. This non-productive time directly impacts shop efficiency and repair turnaround. Instead of focusing on their primary role of repairing vehicles, they are burdened with administrative tasks. A modern system with features like precise location tracking, barcode scanning, and a centralized, searchable digital catalog eliminates this wasted effort, allowing technicians to find what they need instantly and get back to billable work.

You have inaccurate records leading to lost sales

Manual inventory tracking, whether through paper logs or spreadsheets, is notoriously prone to human error. A simple miscount, a forgotten entry, or a data transposition can create a cascade of problems. Inaccurate records mean you might tell a customer a part is in stock when it isn’t, leading to a broken promise and a lost sale. Conversely, you might reorder parts you already have, leading to unnecessary purchases and surplus stock. These inaccuracies erode trust with customers and create a constant state of uncertainty within your operations. Without a single source of truth for your inventory data, you cannot make informed decisions, which ultimately costs you both money and customer loyalty.

Your operational costs are rising and cash flow is shrinking

The financial consequences of poor inventory management are severe and multifaceted. Overstocking ties up cash in assets that aren’t generating revenue, while stockouts lead to expensive emergency orders with high shipping costs. The time wasted by staff searching for parts or managing chaotic stock translates directly into higher labor costs per repair job. Furthermore, inaccurate purchasing decisions inflate operational expenses. All these factors combine to shrink your cash flow and reduce overall profitability. If you notice your costs are creeping up while your revenue remains flat or declines, your inventory management process is a prime suspect. It’s a silent drain on your business’s financial health that only a systematic, automated approach can fix.

How does modern software bring order to inventory chaos?

Transitioning from manual methods or outdated spreadsheets to a modern inventory management system introduces a new level of control, intelligence, and efficiency into your auto parts business. These advanced software solutions are designed to create an intelligent ecosystem that automates tedious workflows, provides clear visibility into your stock, and delivers the data needed for strategic decision-making. By tackling the root causes of inventory chaos, this technology transforms a major operational headache into a streamlined and profitable part of your business.

By eliminating human error with automation

The most significant advantage of modern software is its ability to automate processes that are highly susceptible to human error. Inventory management requires precision, and automation is the key to achieving it. Features like barcode scanning, VIN tracking, and serial number management ensure that every part is tracked accurately from the moment it arrives to the moment it’s sold or installed. When stock levels get low, the system can be configured to automatically generate purchase orders based on preset thresholds, removing manual administrative work and guesswork. According to the principles of modern inventory management, automation is a requirement because it drastically reduces mistakes in parts counting and ordering, freeing up staff to focus on higher-value tasks like customer service and vehicle repairs.

By providing real-time stock visibility and data

Modern auto parts software provides a centralized dashboard that offers an immediate, up-to-the-minute view of your entire inventory. You can instantly see stock levels, part locations, and usage history without having to perform a manual count or check a spreadsheet. This real-time stock visibility is crucial for making quick, informed decisions. When a customer calls for a specific part, you can confirm its availability with confidence. Technicians can check the system to locate a component without leaving their service bay. This capability extends to managing inventory across multiple locations or warehouses from a single interface, ensuring consistency and control. Some platforms even offer mobile apps, facilitating on-the-go inventory updates and real-time adjustments directly from the shop floor.

By optimizing stock levels with demand forecasting

A core function of advanced inventory software is its ability to help you maintain optimal stock levels. The system analyzes historical sales data and usage patterns to forecast future demand for specific parts. This allows you to avoid both overstocking and stockouts. The software can set dynamic reorder points and low-stock alerts, ensuring you replenish high-demand components before you run out while preventing the accumulation of slow-moving parts. This demand forecasting capability is essential for supporting optimal stock levels, as it ensures capital is invested in inventory that will sell, maximizing storage space and improving cash flow. By stocking smarter, not just harder, you reduce carrying costs and increase inventory turnover.By streamlining operations with integrated automotive parts management software

The true power of modern software is unlocked when it integrates seamlessly with other essential business systems. An integrated solution connects your inventory management with your point-of-sale (POS), accounting, and customer relationship management (CRM) platforms, creating a unified operational workflow. This integration eliminates redundant data entry and ensures that information flows smoothly between departments. For instance, when a part is sold, the inventory is automatically updated, and the transaction is recorded in your accounting software. This level of connectivity is a hallmark of sophisticated auto parts software, which is designed to handle the complexities of the automotive aftermarket, including orders, warranties, returns, and pricing. This holistic approach streamlines every aspect of your business, from the front counter to the service bay and the back office.

By improving repair turnaround and customer satisfaction

Ultimately, all these technological improvements converge on a single, critical goal: enhancing the customer experience. When your inventory is managed efficiently, repair processes are accelerated. Technicians have the parts they need when they need them, minimizing vehicle downtime and reducing delays. This efficiency allows your shop to complete more jobs in less time, increasing throughput and revenue. For customers, this means faster, more reliable service. By preventing stockouts and misorders, you build a reputation for dependability and professionalism. As the data shows, this enhanced customer experience, driven by better part availability and fewer delays, leads directly to greater customer satisfaction and fosters the kind of loyalty that ensures repeat business.

How do you choose the right partner for this digital transformation?

Selecting the right software is only half the battle; choosing the right technology partner to implement it is equally crucial for a successful digital transformation. The ideal partner brings more than just a product—they bring expertise, a forward-thinking approach, and the ability to tailor solutions to your specific business needs. Making the right choice ensures your investment will not only solve today’s problems but also support your company’s long-term growth and evolution.

Look for a provider with cross-industry expertise

While deep knowledge of the automotive sector is vital, a partner with cross-industry expertise can offer invaluable insights and innovative solutions. Experience in related fields like logistics, manufacturing, and enterprise resource planning (ERP) often translates into a more robust and comprehensive approach to problem-solving. Such providers understand the broader supply chain and can implement best practices learned from other complex industries. For example, a partner with a background in enterprise solutions can better handle challenges related to multi-site management, complex supply chains, and large-scale data analytics. This wider perspective ensures your solution is not just functional but truly cutting-edge.

Ensure they can scale solutions as your business grows

Your business is not static, and your inventory management software shouldn’t be either. It is critical to select a partner whose solutions can scale with your company. Whether you plan to open new locations, expand your service offerings, or simply handle a growing volume of parts and repairs, the system must be able to adapt without sacrificing performance or efficiency. Scalability means the software architecture is flexible enough to accommodate more users, larger datasets, and increased transaction volumes. A good partner will discuss your five- and ten-year plans to ensure the platform they provide today will serve as a solid foundation for your future success, preventing the need for a costly and disruptive system replacement down the road.

Select a professional software development company for custom needs

While off-the-shelf software can meet many needs, automotive businesses often have unique workflows and requirements that demand a more tailored approach. This is where partnering with a professional software development company becomes a significant advantage. Such a company can offer custom software development, IT consulting, and system integrations to create a solution that perfectly aligns with your operational processes. They can build custom features, integrate with your existing legacy systems, or develop entire web applications and SaaS platforms to give you a competitive edge. Companies with a proven track record in digital transformation, like the European IT firm Hicron Software, combine advanced technical skills with business process consulting, ensuring the final product is not only technically sound but also drives tangible business value, backed by certifications like ISO 27001 that attest to their reliability and quality.

Is investing in inventory software truly worth it for the future?

In an increasingly competitive and technologically driven market, viewing modern inventory software as a mere expense is a shortsighted perspective. Instead, it should be seen as a strategic investment in the future viability and prosperity of your business. The immediate benefits of efficiency and cost savings are just the beginning. The true value lies in creating a resilient, agile, and intelligent operational framework that positions your company for sustained success.

It creates a foundation for scalable growth

A robust inventory management system is the bedrock upon which scalable growth is built. As your business expands—whether by adding new locations, increasing repair volume, or diversifying your parts offerings—a manual or outdated system will inevitably collapse under the weight of complexity. Modern software is designed for scalability, enabling you to manage an increasing volume of parts and transactions without a corresponding loss of efficiency. It provides the structural integrity needed to support growth, ensuring that your processes remain streamlined and your data remains accurate, no matter how large your operation becomes. This solid foundation allows you to pursue expansion opportunities with confidence, knowing your back-end operations can handle the demand.

It turns inventory data into a strategic asset

In the digital age, data is one of the most valuable assets a business can possess. Modern inventory software does more than just track parts; it collects a wealth of data on sales trends, inventory turnover rates, supplier performance, and seasonal demand fluctuations. With robust analytics and reporting features, the software transforms this raw data into actionable business intelligence. You can identify your most and least profitable parts, optimize your pricing strategies, and make data-driven purchasing decisions. This strategic insight allows you to move beyond reactive problem-solving and begin proactively shaping your business for greater profitability and market responsiveness. Your inventory data ceases to be a simple record and becomes a powerful tool for strategic planning.

It secures a competitive advantage in the modern market

Ultimately, investing in modern auto parts inventory software is about securing your place in the future of the automotive industry. Customers today expect fast, reliable, and transparent service. Businesses still relying on antiquated methods will struggle to meet these expectations and will be outpaced by more agile competitors. By automating workflows, optimizing stock levels, and delivering faster repair turnarounds, you not only improve your bottom line but also build a stronger, more resilient brand. This investment is a definitive step toward future-proofing your business, ensuring you have the control, intelligence, and efficiency needed to thrive in a competitive landscape. It’s not just an upgrade—it is a necessary evolution for survival and leadership in the modern market.