In the modern world of logistics and warehousing, businesses face increasing pressure to optimize their operations. One of the most effective ways to do so is by investing in premium materials for warehousing infrastructure. Whether you’re upgrading shelving units, conveyor systems, or the very building structure, the materials you choose can have a significant impact on productivity and long-term cost savings.

In this article, we’ll explore the various ways in which smarter warehousing, fueled by high-quality materials, can deliver impressive returns on investment (ROI).

The Direct Impact of Premium Materials on Productivity

The primary goal of any warehousing operation is to move goods efficiently. From the moment products arrive in the warehouse to when they are shipped out, speed and accuracy matter. Premium materials play a key role in this process.

For instance, strong and durable shelving units made of high-quality steel or reinforced materials can carry heavier loads without the risk of collapse or damage. This means fewer disruptions due to equipment failure, fewer product losses, and fewer accidents. Reliable materials can enhance workflow, allowing for smoother operations and minimizing downtime.

Additionally, premium materials often have enhanced properties, such as resistance to wear and corrosion. This leads to reduced maintenance costs over time and allows warehouse managers to focus on operational improvements rather than repairs and replacements.

Durability Reduces Long-Term Expenses

When it comes to warehousing, durability isn’t just a matter of convenience—it’s a matter of cost. Premium materials are more robust, which reduces the frequency of replacements. This is a crucial factor in lowering long-term costs.

For example, steel shelving systems, as opposed to cheaper alternatives, have a much longer lifespan. They can withstand the harsh conditions found in warehouses, including temperature changes, humidity, and the constant movement of goods. Similarly, high-quality flooring materials, such as reinforced epoxy, can withstand the wear and tear of heavy traffic and constant movement of machinery.

By investing in premium materials initially, businesses can save money in the long run by avoiding frequent repairs or replacement costs that can eat into profit margins. A quality investment upfront can translate into a much lower total cost of ownership.

Boosting Worker Efficiency and Safety

A lesser-discussed but crucial aspect of warehousing is worker safety and efficiency. With premium materials, safety and workflow improvements naturally follow. High-quality materials in racking systems, for example, often result in better organization, easier access to inventory, and reduced strain on workers.

For instance, adjustable pallet racks with premium components make it easier for warehouse workers to find and retrieve products quickly, reducing the time spent navigating shelves. In turn, this boosts productivity. Additionally, premium materials in flooring, shelving, and storage units can contribute to smoother surfaces, reducing the chances of accidents like slips or falls.

Employee morale is another factor that can improve with the use of superior materials. When workers feel safe and see that their employers are investing in high-quality equipment, their sense of well-being and productivity typically increases.

Premium Materials and Energy Efficiency

Energy costs are a significant concern for warehouses. The size of these facilities often means high electricity usage, especially when it comes to lighting, heating, and cooling. Premium building materials such as insulated panels, energy-efficient lighting systems, and high-performance windows can significantly reduce energy consumption.

By utilizing insulation materials with a higher R-value, a warehouse can maintain more consistent temperatures and reduce heating and cooling costs. Additionally, modern LED lighting systems, which are made from high-quality components, consume far less energy than traditional lighting, further lowering energy expenses.

The reduction in energy consumption not only leads to cost savings but also supports sustainability efforts. Many businesses today are looking for ways to reduce their environmental footprint, and investing in energy-efficient materials for warehousing infrastructure is an effective way to do so.

The Role of High-Quality Equipment in Streamlining Operations

Equipment used in warehousing—such as forklifts, automated picking systems, and conveyor belts—can be significantly impacted by the quality of materials they are made from. Premium materials allow for the construction of more reliable, efficient, and long-lasting equipment.

For example, a forklift with high-quality components will experience fewer breakdowns, reducing repair costs and downtime. Similarly, high-end conveyor systems made with durable materials can keep products moving seamlessly, ensuring a steady flow of goods through the warehouse.

The ROI here is clear: superior equipment lasts longer, requires less maintenance, and increases operational efficiency.

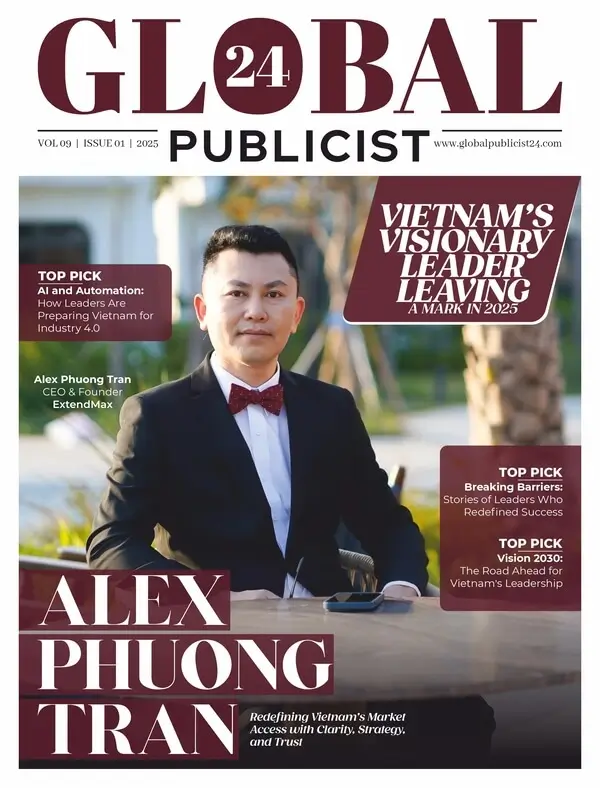

Iron Bull Manufacturing: Setting the Standard for Premium Warehousing Materials

For businesses looking to upgrade their warehousing infrastructure, working with reputable suppliers of premium materials is essential. Companies like Iron Bull Manufacturing provide high-quality solutions that cater to the needs of warehouses, offering everything from industrial-grade shelving to durable equipment. Their products are built to last, ensuring that your investment pays off in terms of reliability and long-term savings.

Choosing a partner like Iron Bull Manufacturing can be a game-changer in terms of elevating your warehouse’s productivity while driving cost-efficiency.

Improved Inventory Management Through Premium Materials

Inventory management is at the heart of warehousing operations. Efficient inventory systems help businesses reduce stock-outs, minimize overstocking, and improve order fulfillment. Premium materials contribute to better, more organized inventory management systems.

For instance, high-quality shelving systems with customizable features allow businesses to organize goods based on size, weight, or frequency of use. This results in quicker access and more efficient stock rotation, reducing the time spent locating products. Moreover, premium materials in inventory tracking systems (such as RFID tags or barcode scanners) improve accuracy and speed during stock-taking, ensuring that businesses have a more precise view of their inventory levels.

Better inventory management also leads to less waste. Products are less likely to become damaged in high-quality storage systems, and inventory turnover can be better managed, further contributing to cost savings.

High-Quality Materials and Scalability

A warehouse that is built with premium materials is also better equipped to handle growth. Scalability is an essential consideration for businesses planning to expand their operations. Whether you’re increasing your product range, storing larger quantities, or scaling up your workforce, the infrastructure needs to accommodate these changes.

Investing in high-quality materials ensures that your warehousing system is flexible enough to grow with your business. From modular shelving that can be expanded to durable flooring that can withstand higher traffic loads, premium materials provide the foundation for scalability without the need for constant reinvestment in infrastructure.

For more insights on optimizing warehouse operations, refer to the American Logistics Association.

Conclusion

The return on investment (ROI) from smarter warehousing through premium materials is undeniable. By enhancing productivity, cutting long-term costs, boosting worker efficiency, improving energy usage, and streamlining operations, high-quality materials offer significant advantages for businesses.